Case Studies

Endless Possibilities.

Just a few of the mobile solutions we've helped engineer. If you can envision it, chances are we can build it.

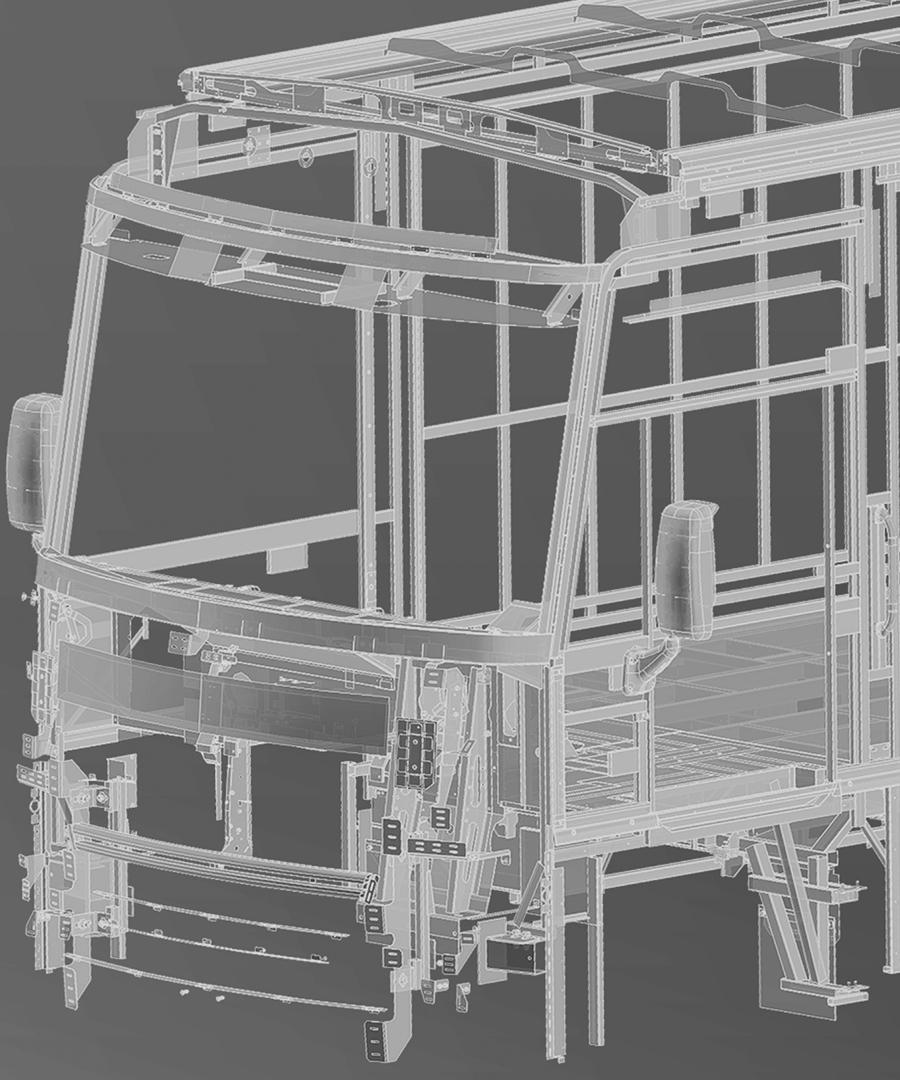

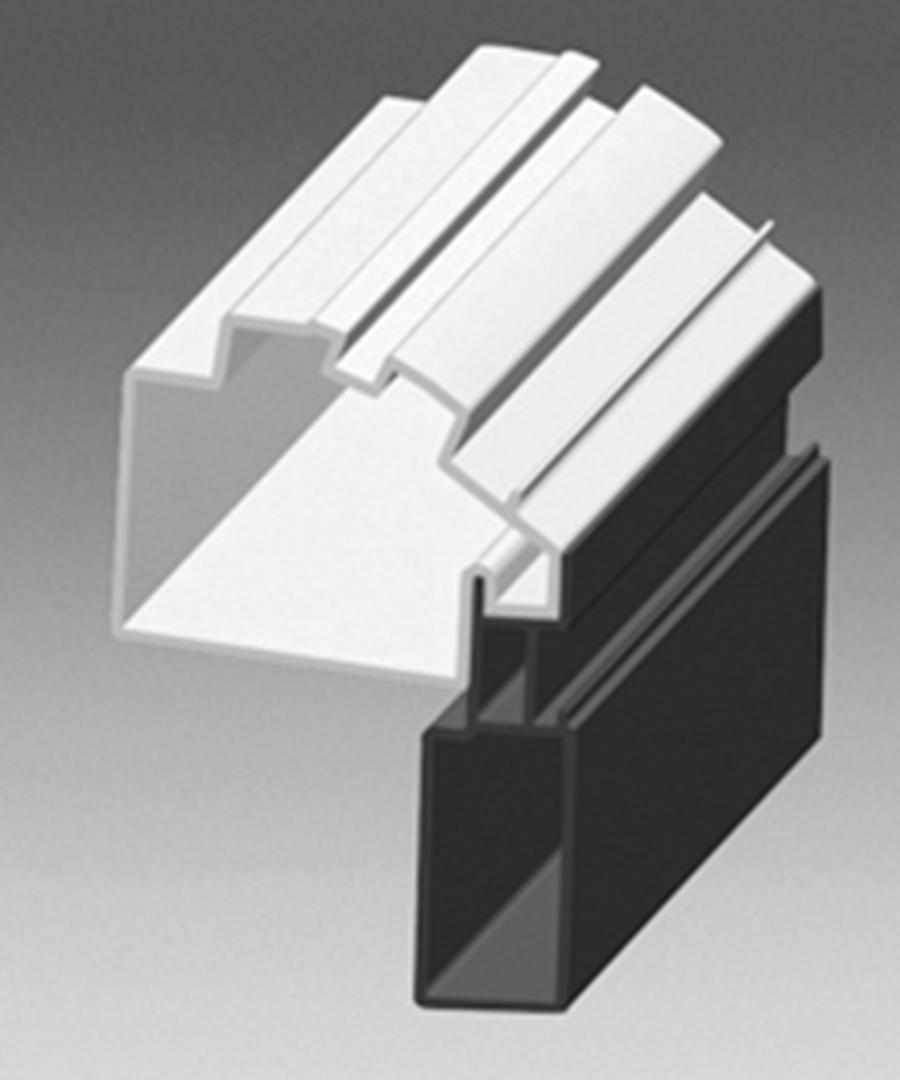

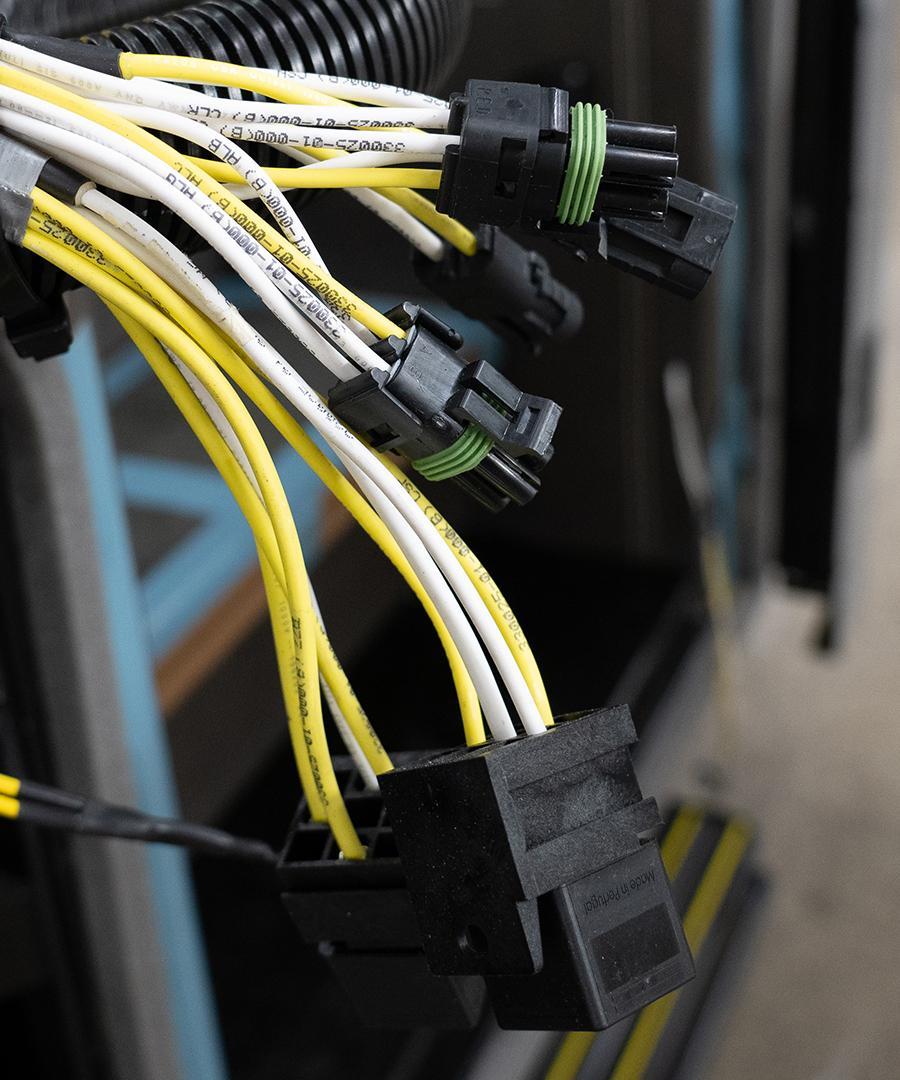

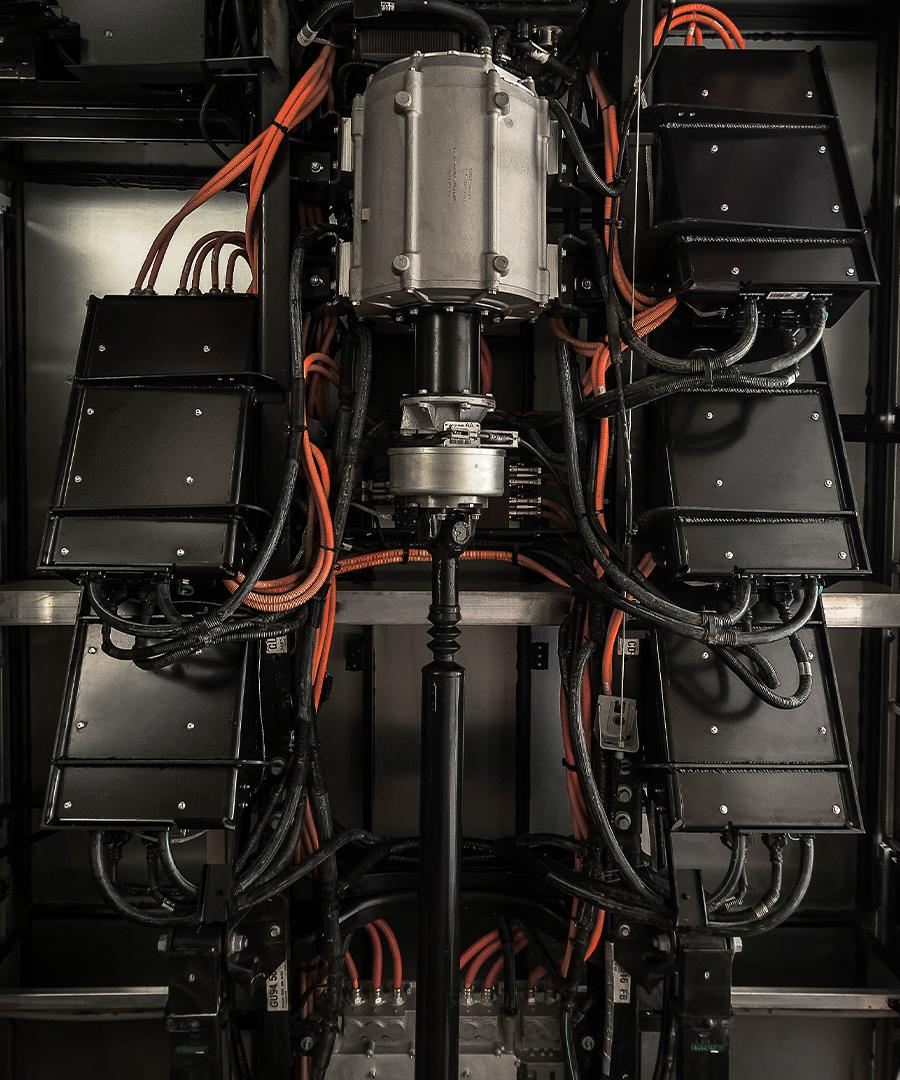

Our trademark Thermo-Panel® wall construction sandwiches the welded aluminum framework, air ducts and insulation between the interior and exterior walls to create strong, durable, and lightweight sidewalls.

Just a few of the mobile solutions we've helped engineer. If you can envision it, chances are we can build it.

Winnebago works closely with the industry's leading upfitters, building customized commercial shells to suit specific applications. We can provide introductions to various upfitting partners.

Connect with a Winnebago Specialty Vehicle Representative to see how we can help bring your vision to life.